Kungfugerbil

New member

Hello all.

I've just started looking over my puma for the first time after picking it up a few weeks back. I've stripped out the interior to be greeted with the following:

Mostly surface rust without penetration or weakening the structure. On the drivers side there is a hole that you could poke a biro through but I'm sure if I gently cleared away some of the flakes a bratwurst would clear it without damage. Not good:

The same patch from underneath:

So, my question is - which of the following is the best approach?

1. Get it pro welded by a decent garage

2. do a DIY MIG repair on it

3. Weld in a brand new box section joining the sills for the rear mounts and turn it into a track car

4. Strip the car for parts and send it to the puma graveyard

Thoughts? Cheers in advance

I've just started looking over my puma for the first time after picking it up a few weeks back. I've stripped out the interior to be greeted with the following:

Mostly surface rust without penetration or weakening the structure. On the drivers side there is a hole that you could poke a biro through but I'm sure if I gently cleared away some of the flakes a bratwurst would clear it without damage. Not good:

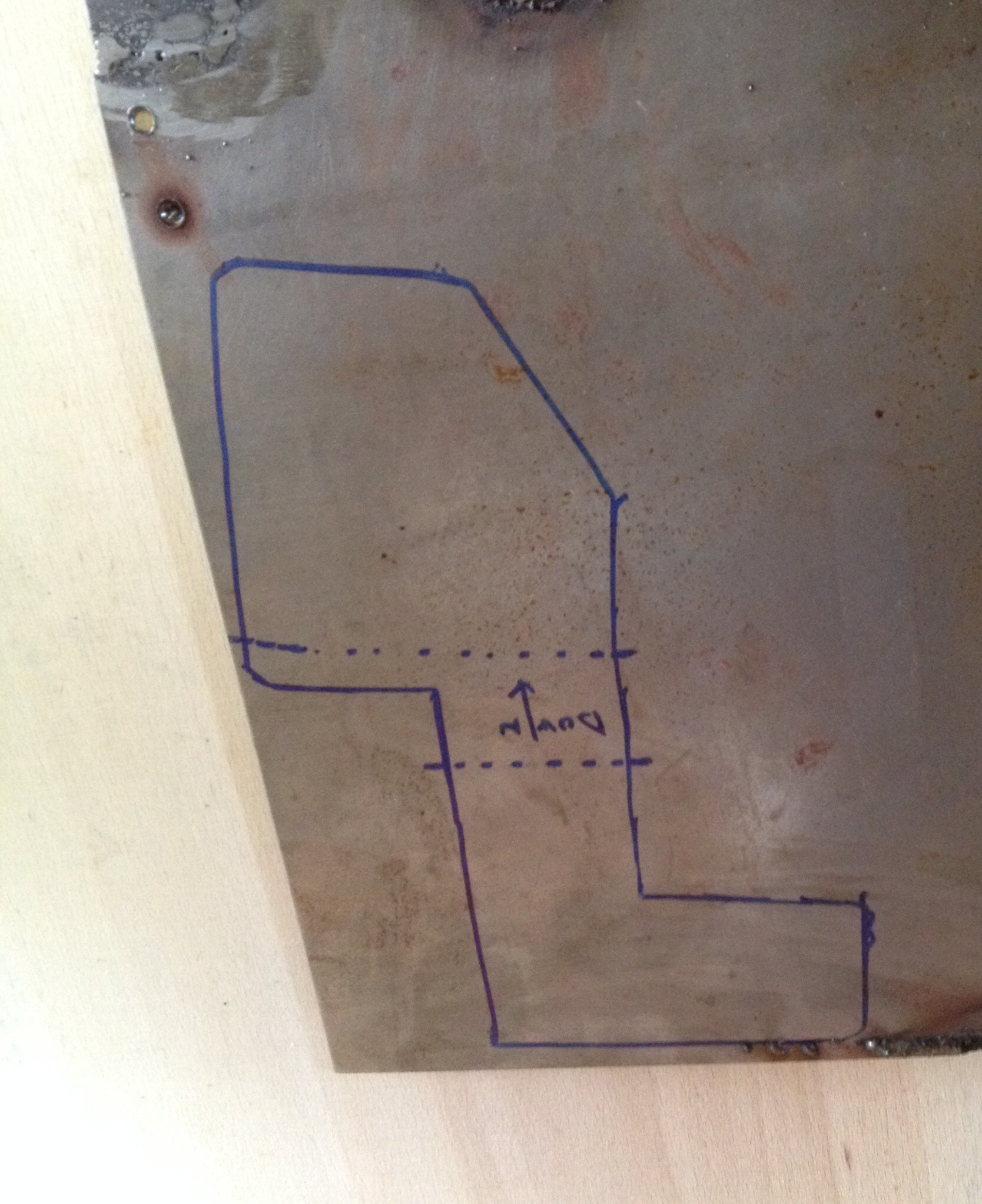

The same patch from underneath:

So, my question is - which of the following is the best approach?

1. Get it pro welded by a decent garage

2. do a DIY MIG repair on it

3. Weld in a brand new box section joining the sills for the rear mounts and turn it into a track car

4. Strip the car for parts and send it to the puma graveyard

Thoughts? Cheers in advance