.AleX.

New member

- Joined

- May 6, 2016

- Messages

- 23

Hello from France and sorry for my poor english

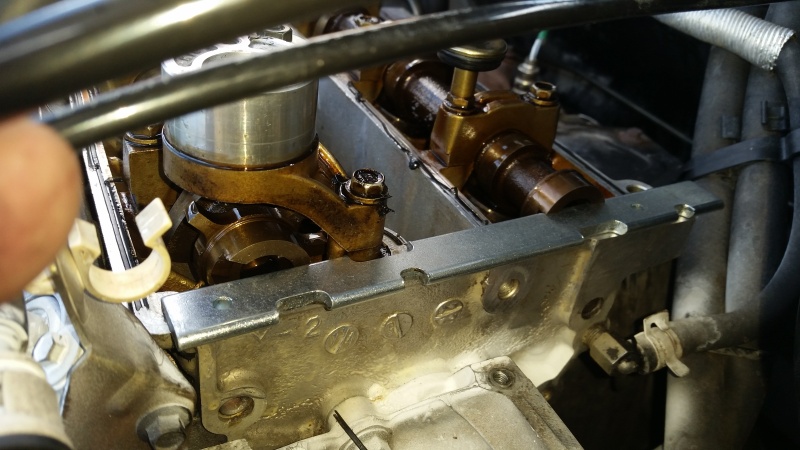

I've bought a Puma one month ago and I've started a 'full servicing' on it.

This is a 2001 October model, with 1.7L and 160oooKm, I'm 40 and this is my first 'Fun and sport car' !

Because of minimal maintenance on it, I have not yet really use it...

According to documents provided with the car, the timing belt have not be replaced since the car was produced !

I'll replace it tomorrow !

By the way, I've already made some servicing :

cheap 10W40 'non name' oil from supermarcket replaced by Castrol 5W30

coolant liquid was.. water ! Replaced by pink one

front brake disc totally out of wear, replaced by Brembo new one.

brake fluid totally replaced too (and for clutch of course)

lot of minor things

For french speakers, my major thread is on "Planète Puma" forum http://www.planetepuma.com/viewtopic.php?f=6&t=6809

Many thanks to all peoples here for thread with a lot of good information for this lovely car

I've bought a Puma one month ago and I've started a 'full servicing' on it.

This is a 2001 October model, with 1.7L and 160oooKm, I'm 40 and this is my first 'Fun and sport car' !

Because of minimal maintenance on it, I have not yet really use it...

According to documents provided with the car, the timing belt have not be replaced since the car was produced !

I'll replace it tomorrow !

By the way, I've already made some servicing :

cheap 10W40 'non name' oil from supermarcket replaced by Castrol 5W30

coolant liquid was.. water ! Replaced by pink one

front brake disc totally out of wear, replaced by Brembo new one.

brake fluid totally replaced too (and for clutch of course)

lot of minor things

For french speakers, my major thread is on "Planète Puma" forum http://www.planetepuma.com/viewtopic.php?f=6&t=6809

Many thanks to all peoples here for thread with a lot of good information for this lovely car