So another update..

After getting the car running and all things being well it was left on the driveway. Few days later I was out for the evening and it rained, came home to find the car battery flat as the alarm had been going off. I knew the car had some leaking issues shall we say but this was a little silly.

So put the car battery on charge and went inside for a while. Half hour later came back it to find the fuel pump running and the auxiliary fusebox relays clicking like crazy. Water had tracked down the wiring loom on the passenger side due to a massive hole through one of the bulkhead grommets, it had then run into the engine loom relays that were just hanging there and caused them to fail and get stuck on.

So with that and always knowing that the wiring on this car was interesting to say the least, it was time to strip it apart and find out what's going on.

Some of the photos are a little 'misty' as my phone was playing up so apologies for that, but hopefully you'll get the idea.

Interior out ready for dash to come out, and some of the messes I will need to sort.

Battery box was a mess to fit a larger battery than it was made for

Lack of airbag module means the drivers airbag is useless, seat restraints had also been cut out so I made the decision to remove it all and at some point change the steering wheel for something more desirable!

Once I got the dash out I realised it had seen better days, it had been hacked about all over the place. So a new one was sourced to be refitted

So with the dash out and all the wiring exposed I can now begin to repair and remove as required, the plan is to remove the old 1.7 ECU and all associated wiring, remove airbag wiring, repair any bodged connections and re-jig wiring for the conversion... Properly this time!

I'm also going to address the engine bay wiring as that is a little less than desired!

So I got to work and this is what I managed to get rid of

Decided to upgrade to a new battery, something a little smaller for the boot

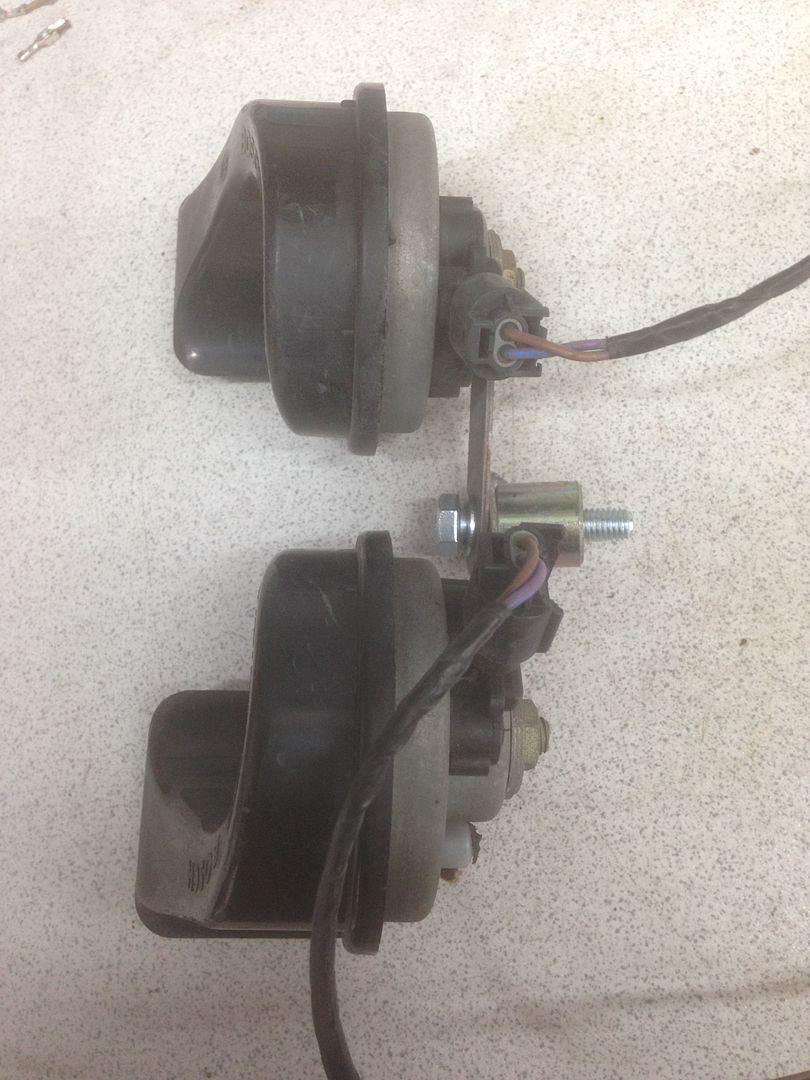

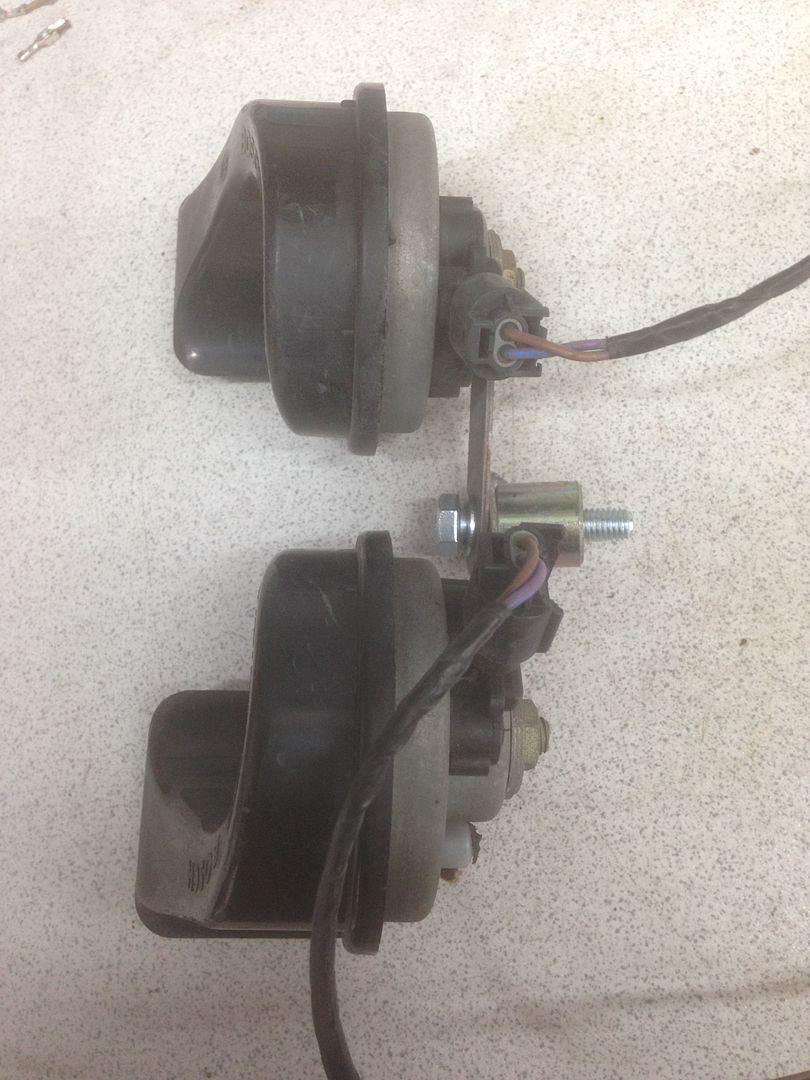

Wiring to the horn was a bit suspect and the horn itself, so replaced with a newer dual tone item

This was the cable between the alternator and starter.. It had 4 joins in it!

More of the mess

Strange battery earth cable

Some interesting wiring in the boot for the fuel pump.. Changing cable sizes

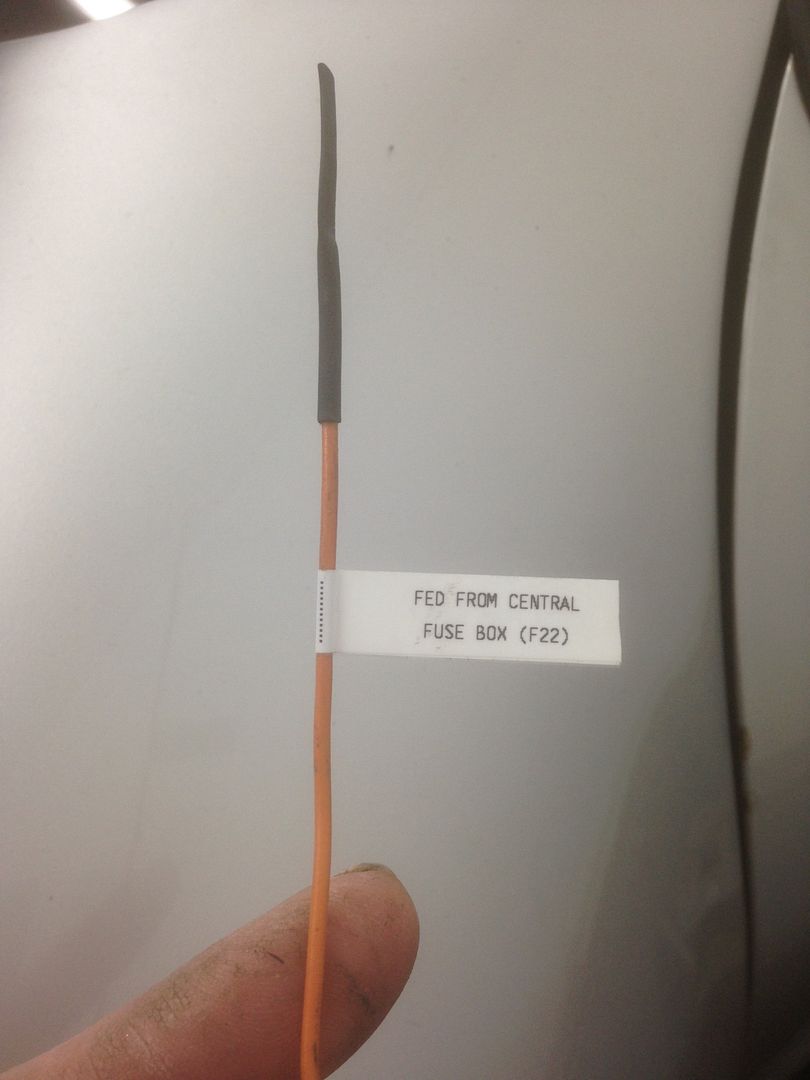

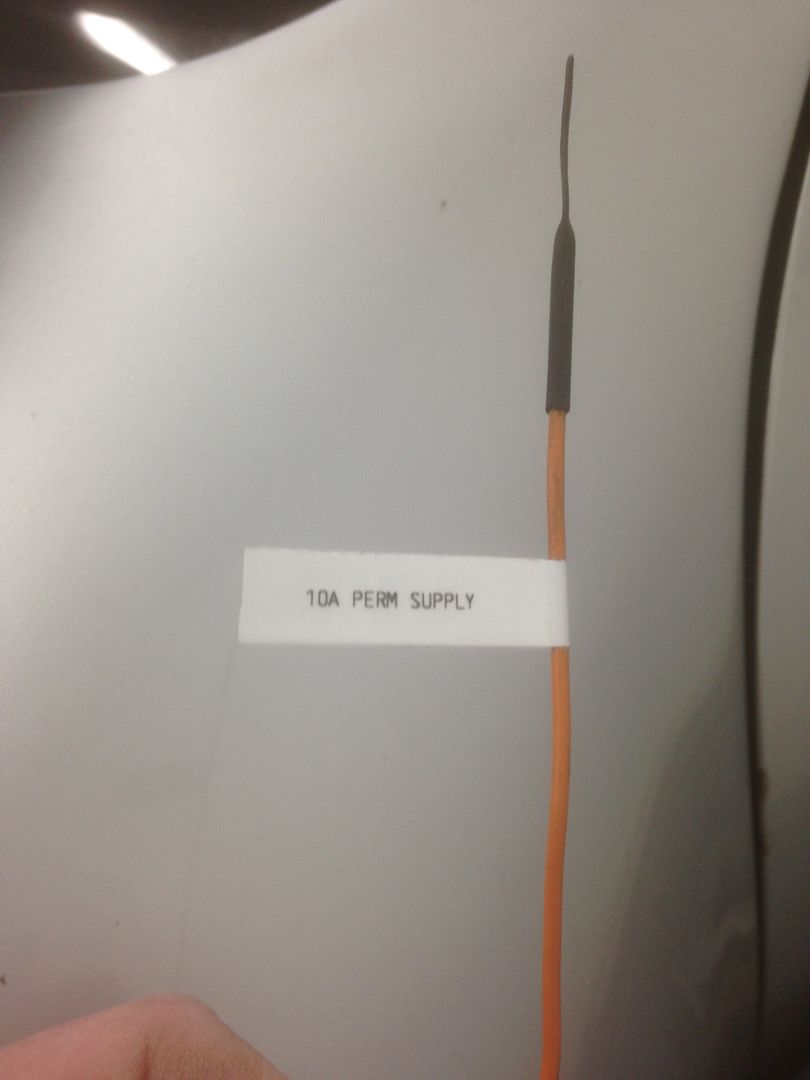

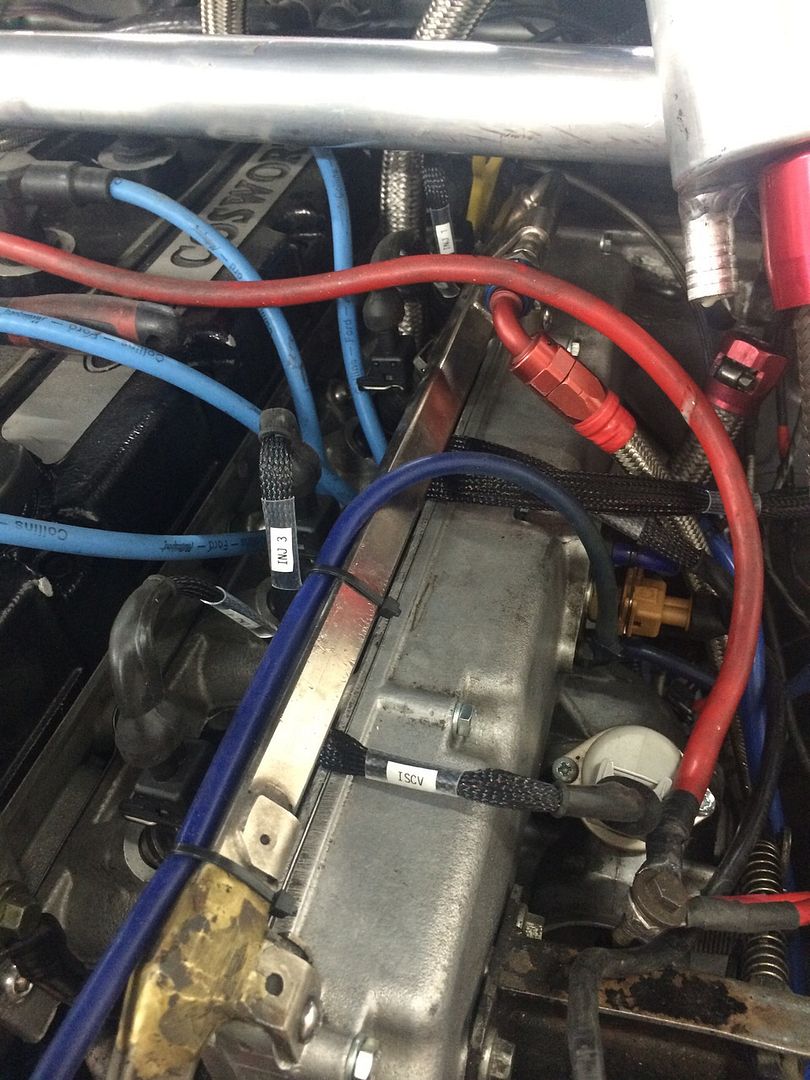

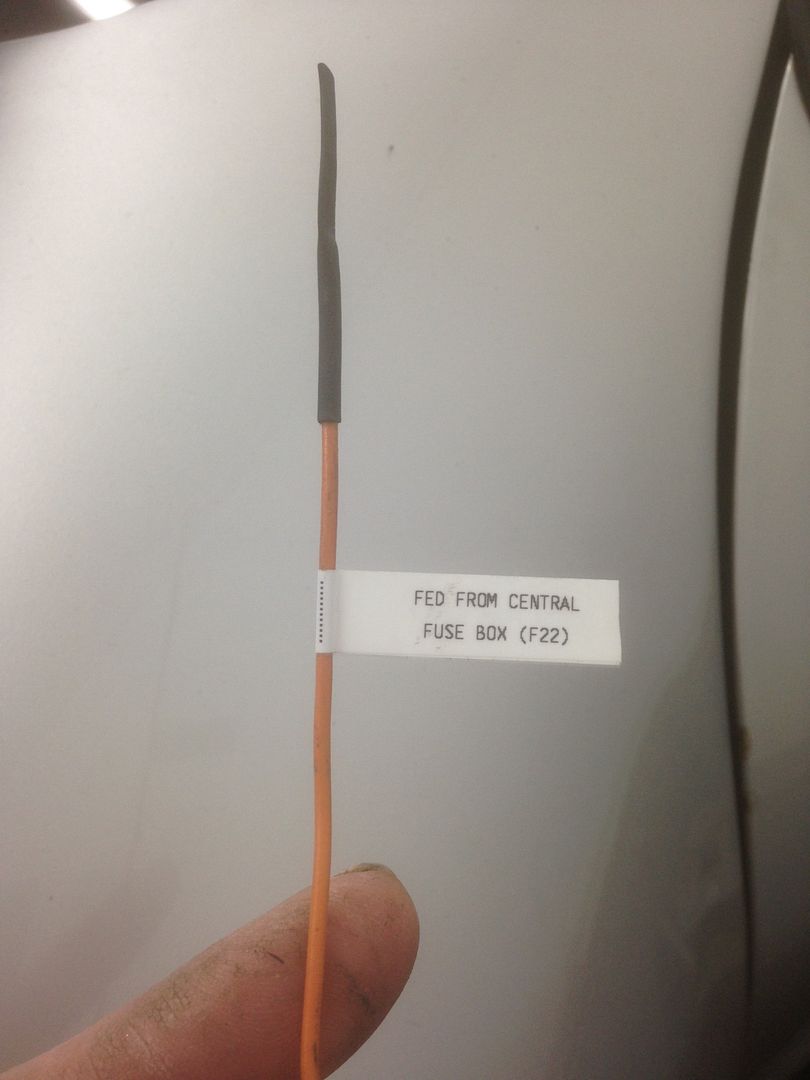

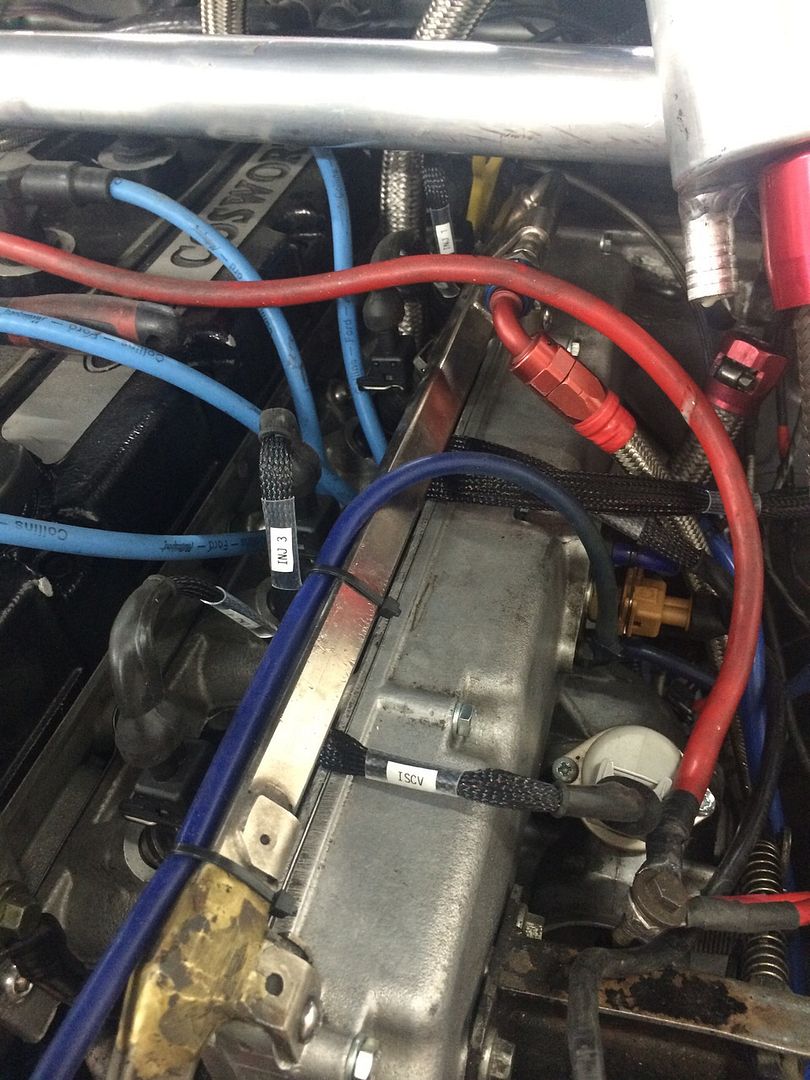

Using cable flags to identify wires in the future

Might have something to do with why the 12v socket doesn't work

Although it doesn't look much this is towards the end of the loom tidying.. The larger red cable has now been removed

Wiring repairs to the car loom.. Soldered joints and heat shrunk

Loom starting to get taped up and tidied

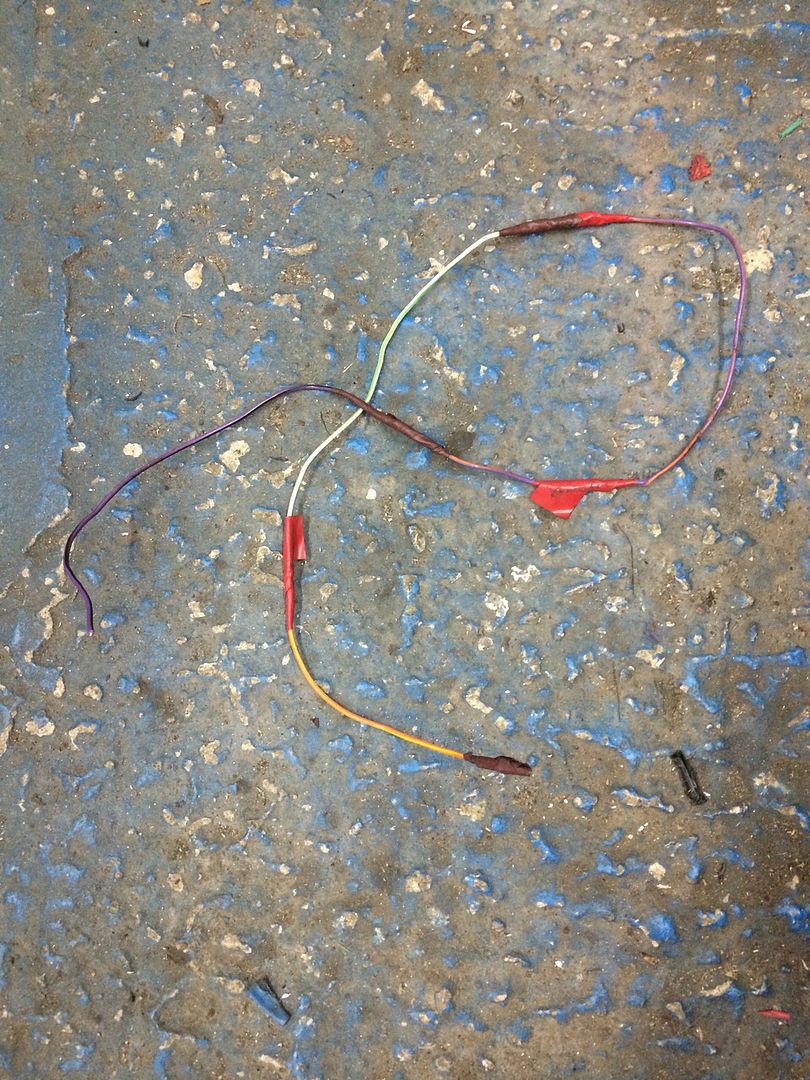

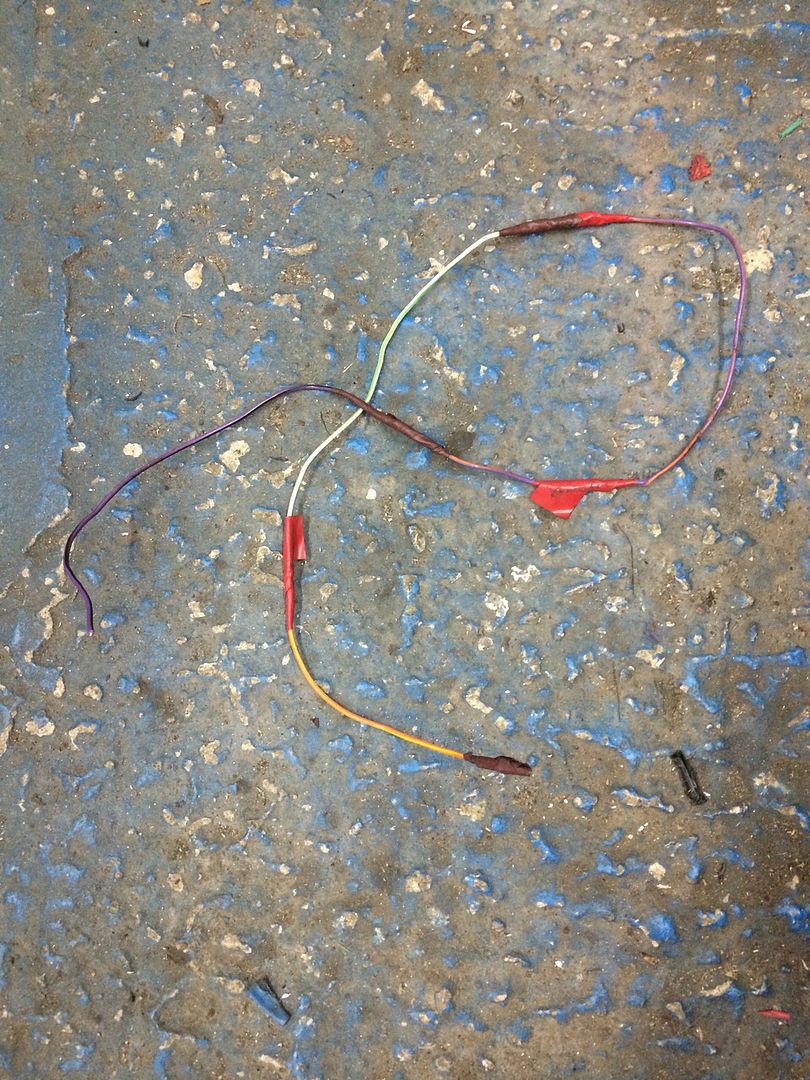

This is the small loom for the variable intermittent wiper, seen better days so made a new one

New alternator cable made ( only have a photo of one end?!)

Car loom tidied and finished, hopefully you can see the differences!

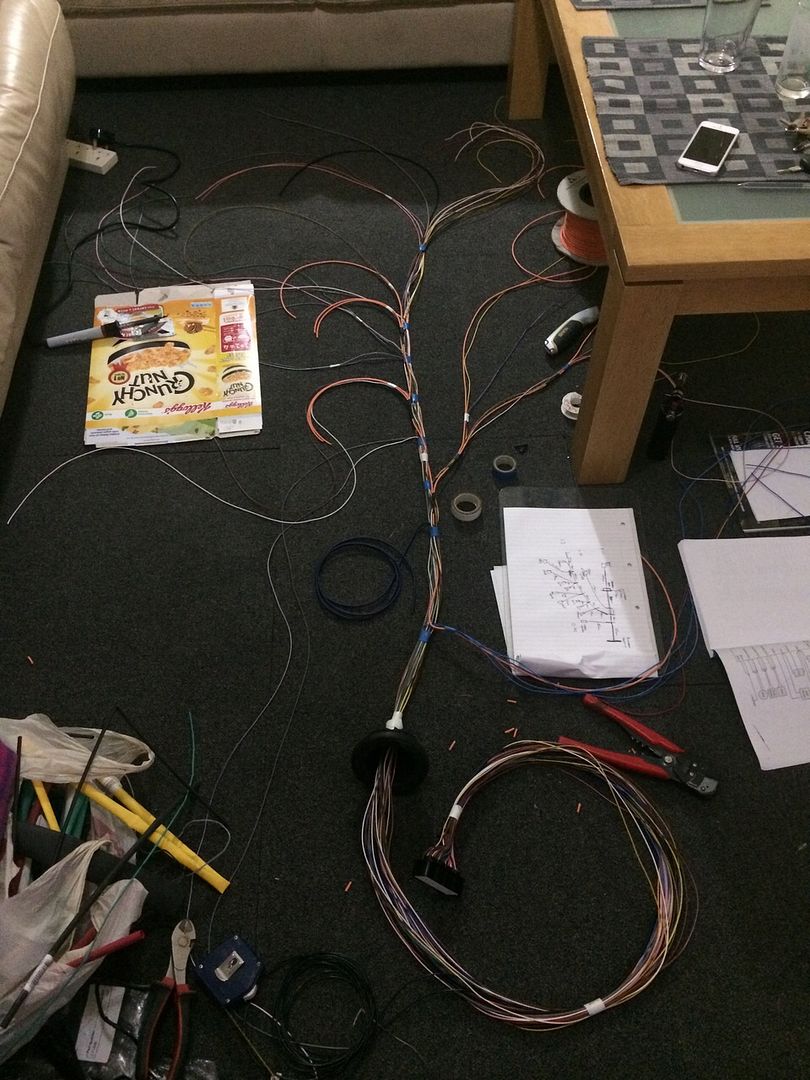

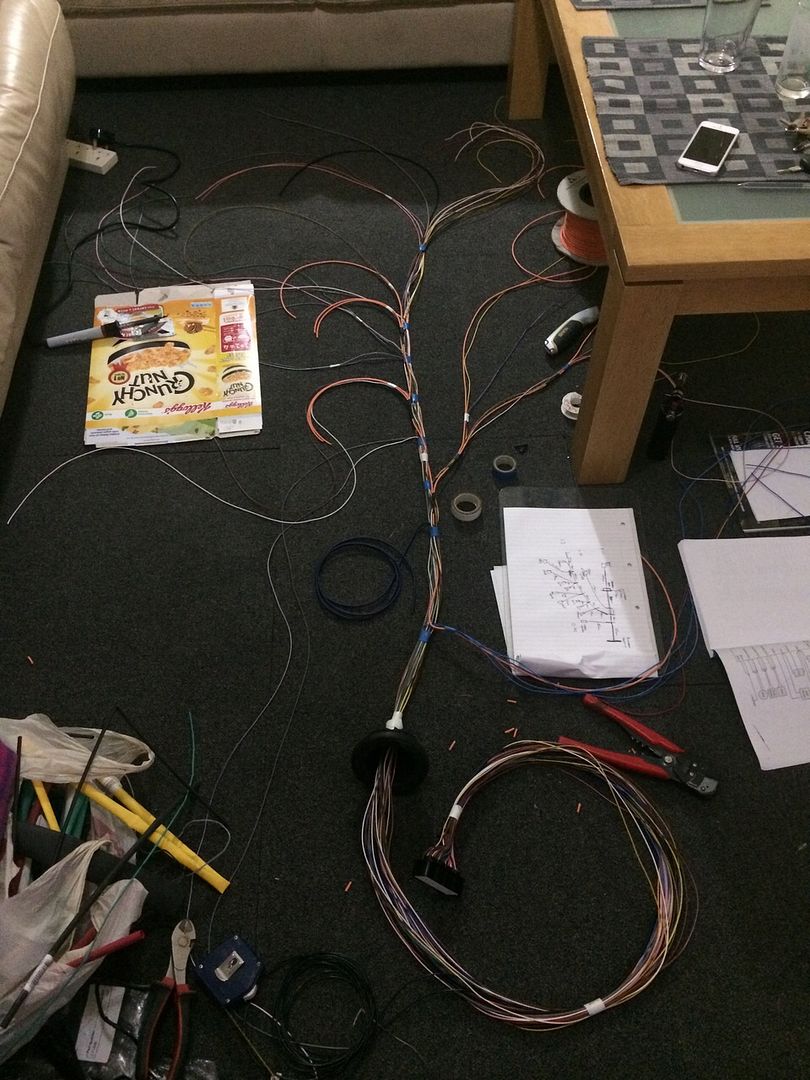

I then made the decision that now was the time to do something about the engine management and loom. The loom was the only area of bad wiring left (excluding planned re-do of the fuel pump wiring) and was letting the engine bay down. So I had a spare omex 600 ECU and thought for now this would work to get a better drive from the engine and allow me to make a new loom. So the parts were bought to make a start.

The all important bulkhead grommet that caused all this to happen in the first place.. Went to the scrapyard to source another one just for this loom

Vacuum pipe fitted in the loom to run boost gauge

A new important addition will be proper boost control.. Not the current bleed valve!

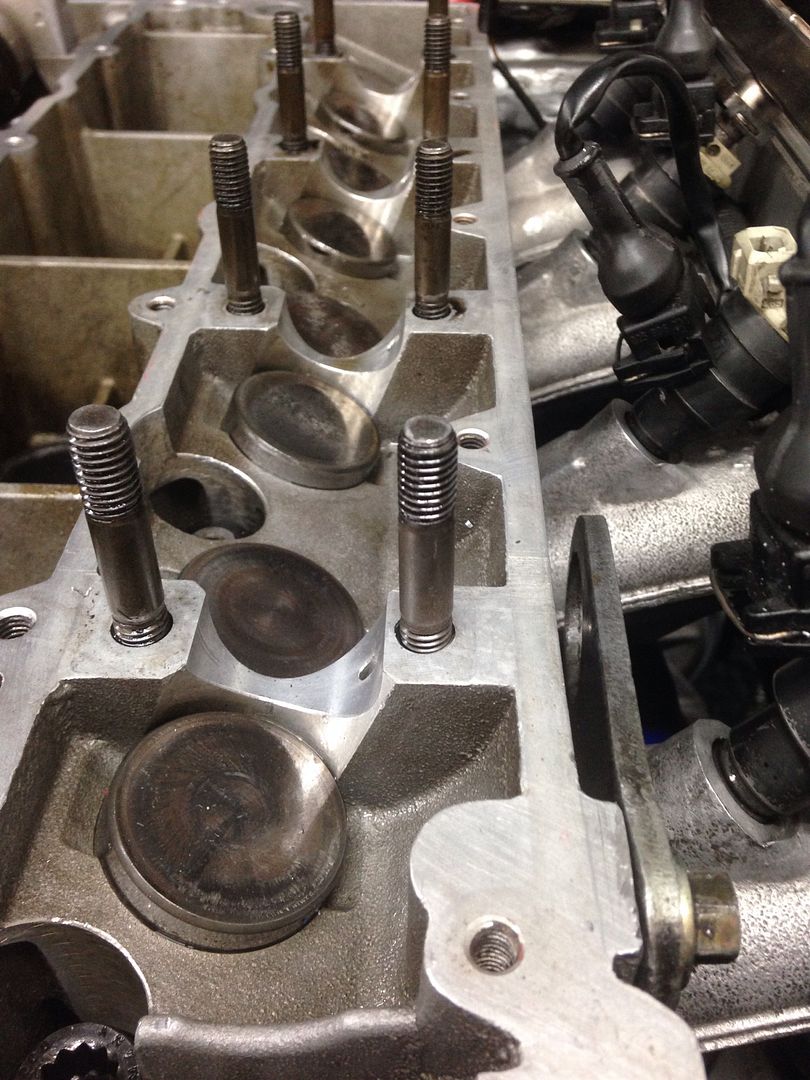

So all this to remove the existing messy loom

Also can now remove the ignition amp for the old management

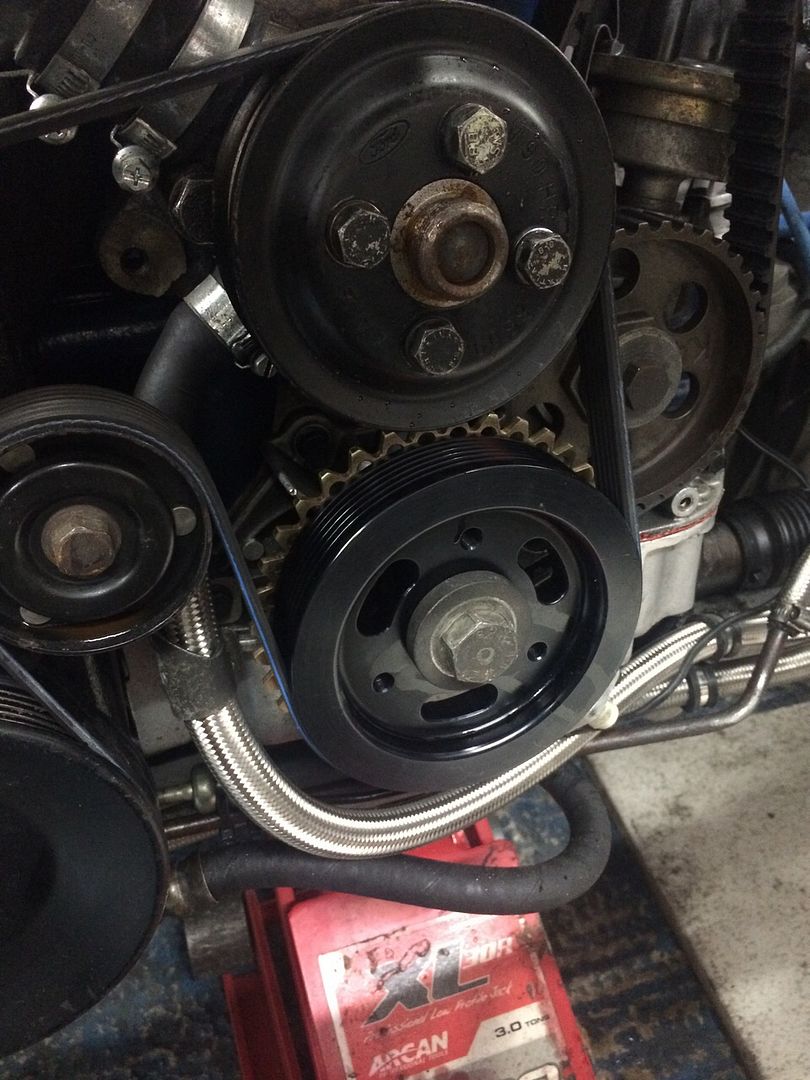

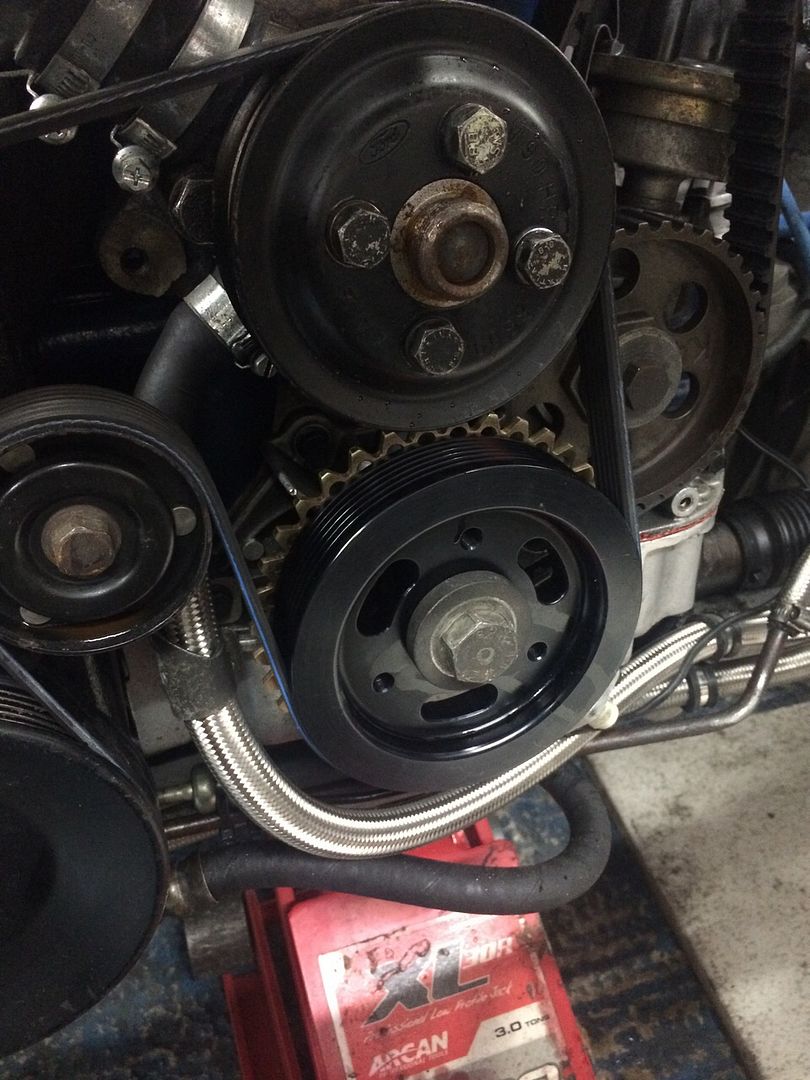

The new management requires a 36-1 toothed wheel for the crank sensor. Thankfully companies make these pulleys off the shelf so a nice black anodised one was bought and fitted

Loom fitted into the bay

So with that all done the interior was fitted back with a nice new dash and looking like a car again.. It was then time to load a base map onto the ECU and get the car running.. I am no mapper, I understand the basics but do not know how to correlate that onto an ECU map. A lot of back and forth with Omex and my tuner and finally I got the car running enough to drive it to the mappers.

One very nervous drive later and the car arrived at the mappers and set up in the hub dyno booth for its mapping session

So... One good session later and the car for once performed faultlessly.. It made 348.8bhp at the hubs and 306 lbs/ft which has been ignition limited to protect the gearbox. It roughly equates to 420/430 bhp at the flywheel.

So with that I had a good drive home and the car is totally different. It is so smooth compared to the old management, and the smell of fuel is far less! It also noticeably used less fuel on the way home!

A good result after a number of weeks of work!

Nearly up to date now so will get the last updates up soon.

Thanks for looking!