So hello, it's been a while!! Turns out time is moving on and I've not done an awful lot. I have a deadline, it must be ready for June 25th for my wedding day. Our cake even has an FRP on the top, although I suspect that will be more solid than #477....

So, where are we at, well, all the suspension, brake lines, shields, tank etc are off and it's ready to be cleaned up. Despite getting good advice from many on here, I still managed to break the fuel line getting the tank out. Bugger.

I've decided to get the bottom soda blasted to do it properly, as well as saving a load of time on my back. It's probably a good job too as it's not at all pretty under there.

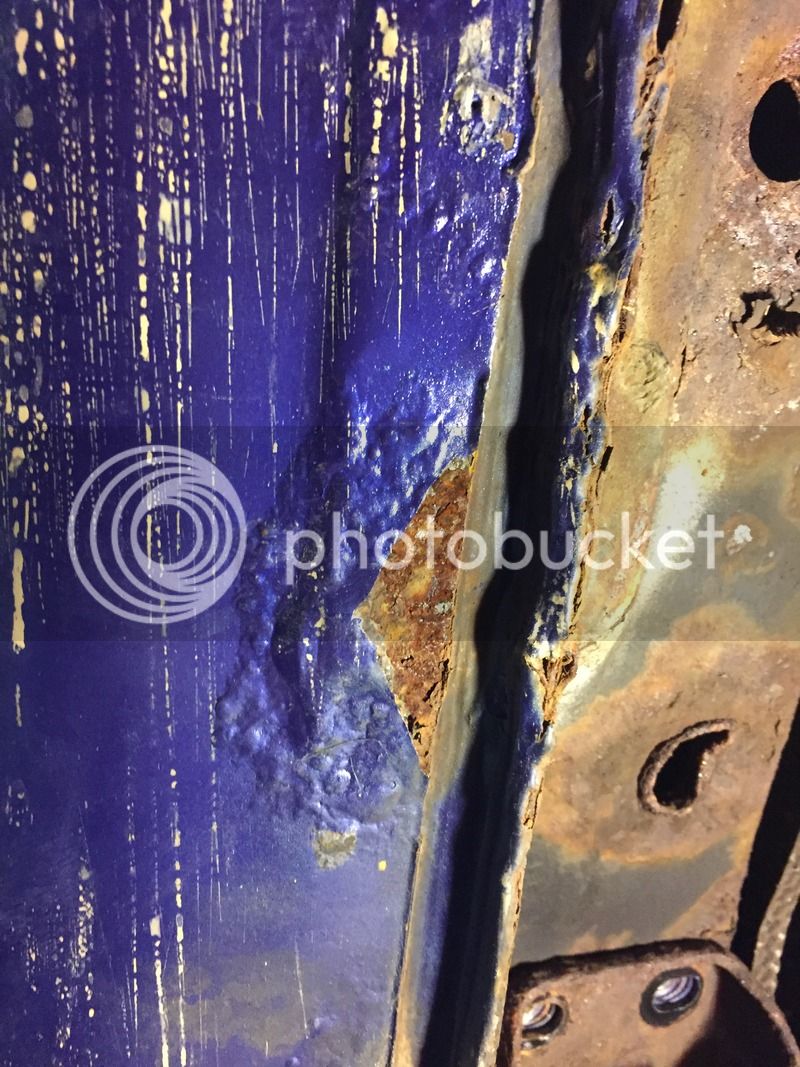

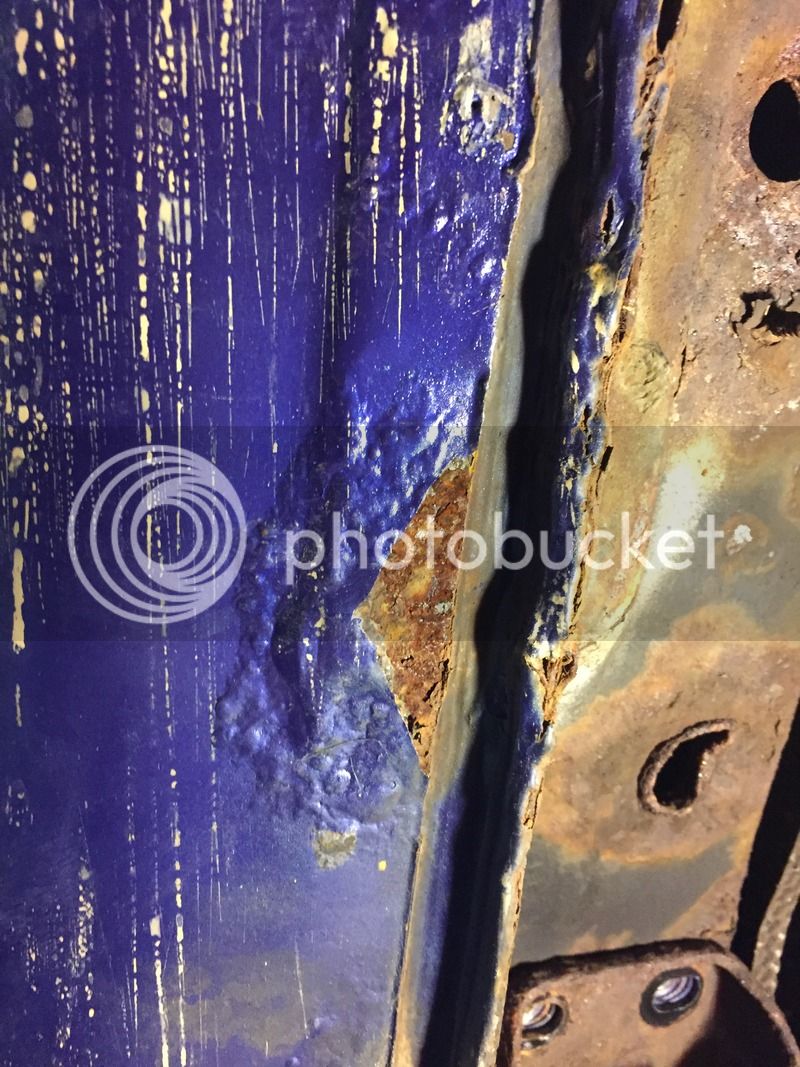

No holes on the floor, it just needs de-rusting and painting up, the drivers side quarter and sill, however, that's a different matter.

So, time to mask up and get cutting... This is before....

During...

After...

You've got to love the fine tolerances that Tickford worked to in massaging the original quarter... i.e. a big chuff off hammer. I'm almost not sure I want to put of the new Ex-pressed Steel sills on as if you're going to have to bash hell out of it to match the original it's a bit of a waste.

So, very little poking later we have this:

Looks bad, and is quite. The inner sill has gone too. Barry came round and suggested that instead of getting my Platinum sound system wired up I should maybe take the speaker box out and see what the inner was like. Not there was the answer as I guess the brown dust isn't a factory finish. By some miracle, however, you can still get them from Ford, so here you go:

Much better than trying to replicate the old panel as if it's as crusty as it looks and feels from above it will be a nightmare.

As part of my on going condition to spend the same as my mortgage each month on parts, I also spent a small fortune on clips for the underside. If you ever need to know the FINIS for clips, here you go:

So there we are, not a lot further forward but lots of work to do. Next step is to cut off the old sill to expose the inner sill, then put a slave axle on and get it down to the soda blasters. It's going to be etch primed at the same time so when it comes back at least I can crack on making it pretty and repairing the sill.